Choose another market or language to see your local offerings.

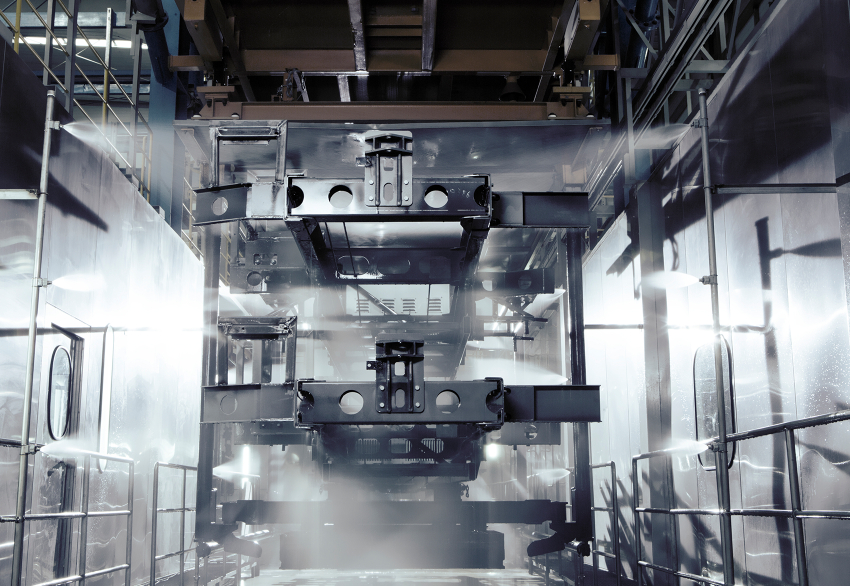

Vehicle Cathodic Electrophoresis

Yutong adopts the same electrophoresis process as Mercedes-Benz, BMW and other top automobile manufacturers, which introduces technology and raw materials completely from Germany and Japan. The entire vehicle (body + frame + chassis included) goes through full immersion cathodic electrophoresis treatment, greatly enhancing the vehicle anti-corrosion and aesthetic effect. The electrophoretic coating can resist more than 1000 hours of salt spray test and prevent structural corrosion such as perforation and rust rot within 10 years.

-

Vehicle Electrophoresis

-

Automatic production line of chassis electrophoresis

Million-kilometer Road Simulation Test

With reference to the development and design of the national test site, and an investment of nearly 40 million yuan, Yutong has built the new vehicle test track, covering about 50,000 m2, as a dedicated site for dynamic vehicle inspection, chassis performance test and other related operations. The construction is conducted by the China Railway Fourth Bureau, which built the Dingyuan national test site. Six major functions characterize the track, namely high-speed test road, comprehensive test road, climbing road, high-ring test road, ESP test field and wading pool. Annual 1-million-kilometer operation reliability test is conducted in the track for new products to ensure the vehicle reliability.

-

High-ring road simulation test

-

Entire vehicle rain test

-

Entire vehicle Wading Test

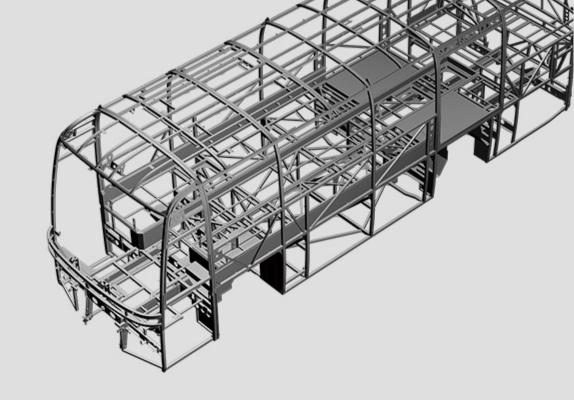

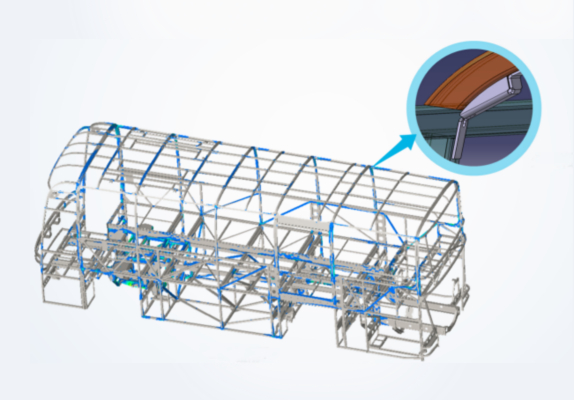

Stable and Reliable Vehicle Body Structure

-

Equipped with a super-strength closed-loop structure, the vehicle rollover angle can be up to 45°with minor rollover deformation.

-

With lightweight technology, 10%-20% weight reduction is realized and over 10% energy consumption reduced.

-

With the optimized aerodynamic streamline structure, the vehicles achieve wind resistance and energy consumption reduced by 10% and 5% respectively.

-

Box structure enables the shear resistance of roof and body frames increased by 50%.

-

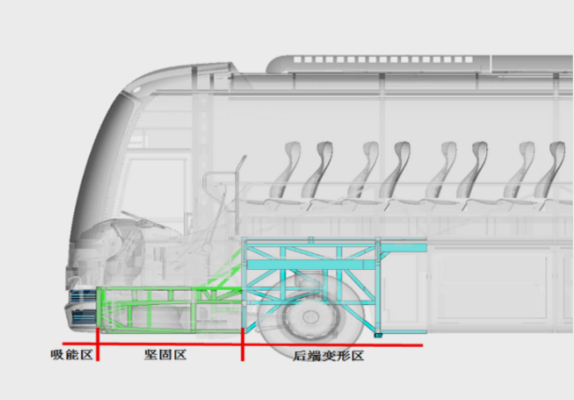

Utilizing through type energy-absorbing frontal collision safety structure, the vehicle collision safety is improved.

-

The Chinese character “日” shaped anti-collision beam structure makes the maximum deformation of side power battery compartment anti-collision beam reduced by about 3 mm.

Durable and Reliable Materials

Application of Technical Processes

-

Argon mixed gas shielded welding ensures welding quality and avoids local failure expansion.

-

The pipe and harness layout and design are based on the separation concept to reduce potential hazards and facilitate maintenance.

-

Electrical protection system guarantees the safety of vehicle harness.